Thermoplastic

Key Benefits

- Individual solutions

- State-of-the-art design technology

- Production of small to large series

- Large capacities available on call

The possibilities of thermoplastics are exceptionally diverse. We offer extensive consulting in order to identify the right material for your product.

We develop materials according to the individual requirements of your product.

As part of this process, we take into account all manner of criteria, such as UV protection, anti-static properties, stabilisation and colour matching. We utilise filler and reinforcing materials as well as bonding agents and compatibilisers. We utilise filler and reinforcing materials as well as bonding agents and compatibilisers.

Know-how that pays off

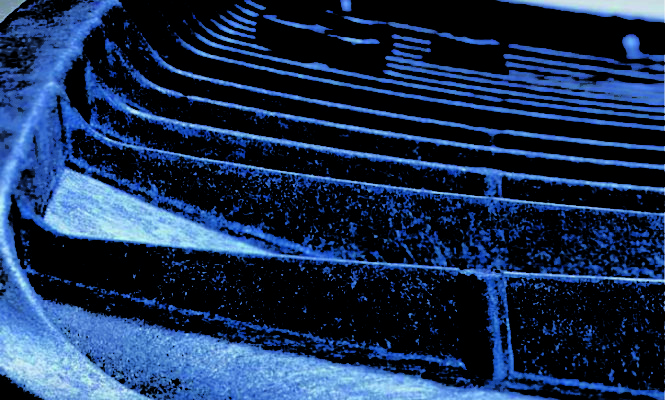

As a WERZALIT customer, you profit from our decades of experience in plastic processing when it comes to designing moulds. By taking both the material and the part into consideration when designing the mould, precisely estimating the shrinkage and warping as well as optimally designing the mould cooling, we ensure the best possible foundation for the production of your product while determining the most favourable manufacturing parameters.

From pixels to mould

We use modern CAD software for mould design:

SolidWorks, Inventor and Autocad.

We have a wide range of programs at our disposal as interfaces:

Iges, Step, Parasolid and Dxf.

We offer other direct interfaces, such as Catia, on request.

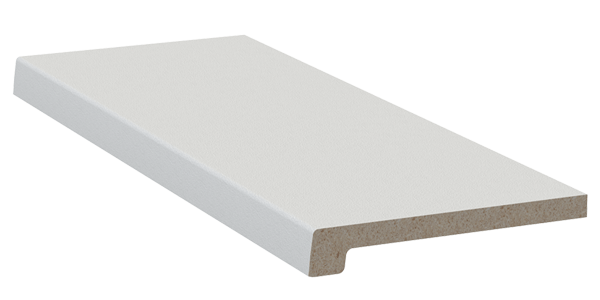

Extensive volume for your product

The finished moulds are used to produce the first samples for your inspection. After approval, we start the production of small to large series on injection moulding machines. Our production capabilities include machines with closing forces from 500 to 1000 t, shot volumes up to 6.5 l and clamping widths up to 1690 mm x 1380 mm.

Dimensions and Properties

| Density: | 900 kg/m 3 |

| Flexural strength: | 32 N/mm 2 |

| E-module (bending): | 1350 N/mm 2 |

| Charpy impact strength: | 105 kg/m 2 |

Reference